This post contains affiliate links. This means I will make a commission at no extra cost to you should you click through and make a purchase [ “As an Amazon Associate, I earn from qualifying purchases.” ]. Read the full disclosure here.

2007 Honda Odyssey AC Compressor GuideMechanic.Com Are you experiencing issues with the air conditioning system in your 2007 Honda Odyssey? The AC compressor is an essential component that plays a crucial role in keeping your car cool and comfortable during those hot summer days.

In this comprehensive guide, we will delve into the details of the 2007 Honda Odyssey AC compressor, providing you with all the information you need to understand its function, common problems, and maintenance tips.

Understanding how the AC compressor works is the first step in troubleshooting any issues you may encounter. The AC compressor is responsible for compressing and circulating the refrigerant, which cools the air before it enters your car’s cabin.

Without a properly functioning compressor, your air conditioning system will fail to provide the desired cooling effect. In the following sections, we will explore the various aspects of the 2007 Honda Odyssey AC compressor in detail, helping you diagnose and address any potential problems.

What is an AC Compressor and How Does it Work?

The AC compressor is a vital component of your 2007 Honda Odyssey’s air conditioning system. It is responsible for compressing the refrigerant gas, which allows it to release heat and cool down the air before it enters the cabin. Understanding the inner workings of the AC compressor will help you troubleshoot any issues that may arise.

See Also: 2002 Honda Odyssey Catalytic Converter

The AC compressor operates based on a simple principle: the refrigerant gas is compressed, causing its pressure and temperature to rise.

As the gas moves through the compressor, it releases heat to the surrounding environment, leading to a decrease in temperature. This cooled refrigerant is then sent to the condenser, where it releases more heat and transforms back into a liquid state.

The liquid refrigerant then flows through the expansion valve, where it undergoes a pressure drop, allowing it to evaporate and absorb heat from the cabin air. Finally, the cycle repeats as the refrigerant returns to the compressor.

The AC compressor is driven by a belt connected to the engine’s crankshaft. When you turn on the air conditioning system, the compressor clutch engages, causing the compressor to start working.

It is important to note that the AC compressor relies on proper refrigerant levels and lubrication to function effectively. Lack of refrigerant or inadequate lubrication can lead to compressor failure and other AC system issues.

Key Points:

- The AC compressor compresses the refrigerant gas, cooling it down before it enters the cabin.

- Compressed gas releases heat, which is subsequently released by the condenser.

- The refrigerant undergoes pressure drops and evaporation to absorb heat from the cabin air.

- The AC compressor is driven by a belt connected to the engine’s crankshaft.

- Proper refrigerant levels and lubrication are essential for the compressor’s optimal functioning.

Signs and Symptoms of a Faulty AC Compressor

A malfunctioning AC compressor can manifest through various signs and symptoms. Recognizing these indicators early on can help you take prompt action and prevent further damage to your 2007 Honda Odyssey’s air conditioning system.

1. Strange Noises

If you hear unusual noises coming from your AC system, such as grinding, squealing, or rattling sounds, it may indicate a problem with the compressor.

These noises can be caused by a faulty compressor clutch, worn-out bearings, or internal component damage. It is essential to address these issues promptly to avoid further damage and potential compressor failure.

2. Warm Air Blowing from Vents

One of the most obvious signs of a failing AC compressor is when warm air starts blowing from the vents instead of cool air. This can occur due to a variety of reasons, such as low refrigerant levels, a malfunctioning compressor clutch, or a refrigerant leak. A thorough inspection of the AC system is necessary to identify and rectify the underlying cause.

3. Excessive Vibrations

If you notice excessive vibrations coming from your 2007 Honda Odyssey’s AC system, it could indicate a problem with the compressor or its mounting.

Internal compressor damage or loose components can cause these vibrations, which are often accompanied by abnormal noises. Ignoring these vibrations can lead to further damage and potential compressor failure.

4. Reduced Cooling Efficiency

If you find that your air conditioning system is not cooling the cabin as effectively as before or takes longer to reach the desired temperature, it may be a sign of a faulty AC compressor.

Reduced cooling efficiency can result from various issues, including compressor wear and tear, refrigerant leaks, or a clogged condenser. A professional inspection is necessary to diagnose the exact cause and address it accordingly.

5. Unusual Odors

A malfunctioning AC compressor can sometimes emit strange odors, such as a musty or moldy smell. This can indicate the presence of mold or bacteria within the AC system, which not only affects the compressor but also poses potential health risks.

See Also: 2009 Honda Accord Catalytic Converter

Prompt action should be taken to clean and disinfect the system to prevent further damage and ensure a pleasant driving experience.

6. AC System Cycling On and Off Frequently

If your AC system frequently cycles on and off without reaching the desired temperature, it may be due to a failing AC compressor.

This can be caused by various factors, including low refrigerant levels, a faulty compressor clutch, or electrical issues. Professional diagnosis and repair are necessary to restore proper functionality to your AC system.

7. Visual Clues

Visually inspecting your AC compressor can sometimes reveal signs of damage or leaks. Look for oil stains, refrigerant leaks, or damaged compressor components.

While these visual clues can provide valuable insights, it is essential to consult a professional technician for a thorough diagnosis and repair.

Key Points:

- Strange noises, such as grinding, squealing, or rattling, can indicate AC compressor issues.

- Warm air blowing from the vents instead of cool air is a common sign of a failing compressor.

- Excessive vibrations can point to internal compressor damage or loose components.

- Reduced cooling efficiency may indicate compressor wear and tear, refrigerant leaks, or a clogged condenser.

- Unusual odors, such as a musty smell, can suggest the presence of mold or bacteria within the AC system.

- Frequent cycling of the AC system without reaching the desired temperature can be a sign of a failing compressor.

- Visual inspection may reveal oil stains, refrigerant leaks, or damaged compressor components.

Common Problems with the 2007 Honda Odyssey AC Compressor

While the AC compressor is a vital component of your 2007 Honda Odyssey’s air conditioning system, it is not immune to problems.

Understanding the common issues that can arise with the AC compressor will help you take the necessary steps to address them promptly and effectively.

1. Compressor Failure

Compressor failure is one of the most severe problems that can occur with the AC compressor. It can be caused by a variety of factors, including inadequate lubrication, excessive wear and tear, electrical issues, or refrigerant leaks. Compressor failure often results in a complete loss of cooling function and requires professional replacement.

2. Refrigerant Leaks

Refrigerant leaks can occur in the AC compressor or other parts of the system, such as hoses, fittings, or the evaporator coil. These leaks not only affect the AC compressor’s performance but also contribute to environmental pollution.

Detecting and repairing refrigerant leaks is essential for the optimal functioning of your AC system and compliance with environmental regulations.

3. Electrical Problems

Electrical issues can affect the AC compressor’s performance and functionality. Problems with the compressor clutch, wiring, relays, or sensors can prevent the compressor from engaging or cause it to work intermittently. Proper diagnosis and repair of electrical problems are necessary to restore the AC system’s effectiveness.

4. Contaminants and Debris

Contaminants and debris can accumulate in the AC system over time, leading to clogged components, reduced cooling efficiency, and potential compressor damage.

Dust, dirt, leaves, and other debris can hinder proper airflow and cause overheating of the compressor. Regular cleaning and maintenance are essential to prevent these issues and ensure the longevity of your AC compressor.

5. Overheating

Overheating is another common problem that can affect the AC compressor. Factors such as low refrigerant levels, inadequate lubrication, or excessive system pressure can lead to compressor overheating. Continuous overheating can cause irreversible damage to the compressor and other components of the AC system.

6. Clutch Malfunction

The compressor clutch is responsible for engaging and disengaging the AC compressor as needed. A malfunctioning clutch can prevent the compressor from working correctly, resulting in a loss of cooling function.

See Also: Honda Civic Wheel Bearing

Common issues with the compressor clutch include worn-out bearings, a faulty electromagnetic coil, or a broken clutch plate.

7. Belt Tension Problems

The AC compressor is driven by a belt connected to the engine’s crankshaft. If the belt is loose or worn out, it can lead to inadequate power transmission to the compressor, affecting its performance. Regular inspection and adjustment of thebelt tension are necessary to ensure proper compressor operation.

8. Improper Refrigerant Levels

The AC compressor relies on the correct amount of refrigerant to function optimally. Insufficient refrigerant levels can lead to poor cooling performance, while overcharging can cause excessive system pressure and potential compressor damage. Regular refrigerant level checks and adjustments are crucial for maintaining the proper functioning of your AC compressor.

9. Lack of Maintenance

A lack of regular maintenance can contribute to various AC compressor problems. Failure to clean or replace the air filters, neglecting system inspections, and ignoring recommended maintenance tasks can result in decreased performance and premature wear and tear of the compressor. Following the manufacturer’s maintenance guidelines is essential for preserving the longevity of your AC compressor.

10. Environmental Factors

Environmental factors, such as extreme temperatures and humidity levels, can impact the performance of your AC compressor.

High temperatures can cause the compressor to work harder, increasing the risk of overheating and failure. Additionally, moisture and humidity can lead to corrosion and damage to the compressor and other AC system components.

Taking precautions, such as parking in shaded areas and using sunshades, can help mitigate these environmental effects on your AC compressor.

Key Points:

- Compressor failure can occur due to inadequate lubrication, wear and tear, electrical issues, or refrigerant leaks.

- Refrigerant leaks in the compressor or other parts of the system can affect performance and contribute to environmental pollution.

- Electrical problems can prevent proper compressor engagement or cause intermittent operation.

- Contaminants and debris can lead to clogged components, reduced cooling efficiency, and potential compressor damage.

- Overheating of the compressor can result from low refrigerant levels, inadequate lubrication, or excessive system pressure.

- Malfunctioning compressor clutches can lead to a loss of cooling function.

- Loose or worn-out belts can affect power transmission to the compressor.

- Improper refrigerant levels can impact the compressor’s performance and longevity.

- Lack of maintenance, such as neglecting filter replacements and system inspections, can contribute to compressor problems.

- Extreme temperatures, humidity, and moisture can affect the compressor’s performance and lead to corrosion and damage.

DIY Troubleshooting Tips for AC Compressor Issues

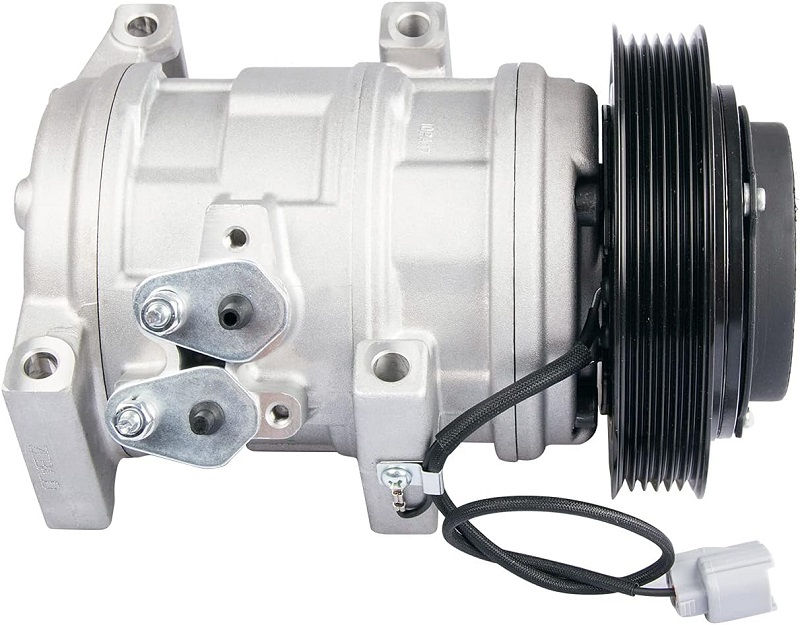

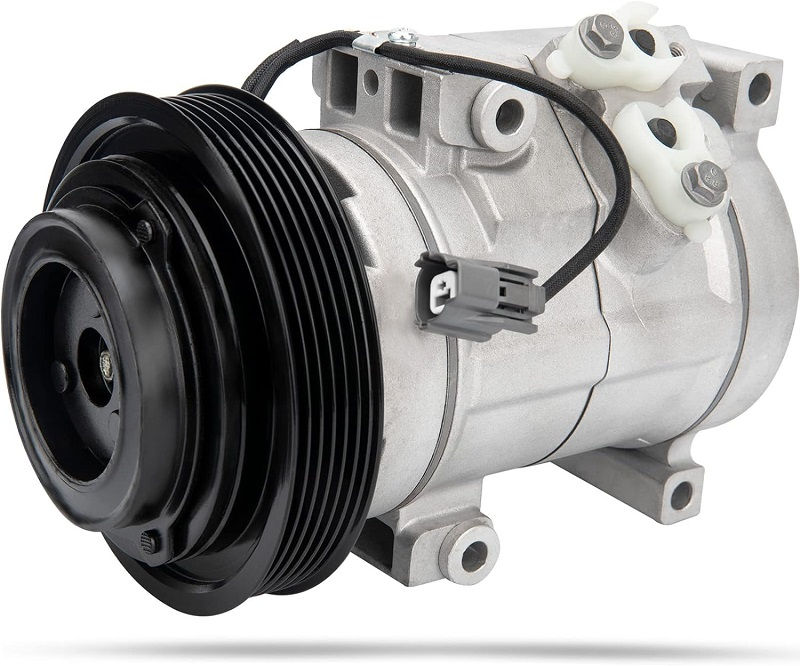

Check out this AC Compressor w/A/C Drier For Honda Odyssey 2005 2006 2007 – BuyAutoParts 60-86385R2 NEW

While certain AC compressor problems require professional assistance, there are several troubleshooting steps you can take yourself to identify and potentially resolve minor issues.

These DIY tips can help you save time and money while ensuring the optimal functioning of your 2007 Honda Odyssey’s AC system.

1. Check the Compressor Clutch

Start by visually inspecting the compressor clutch. Ensure that it engages and disengages properly when the AC system is turned on and off.

If the clutch does not engage, it may be due to a faulty electromagnetic coil or wiring. In such cases, professional repair is necessary.

See Also: 2009 Honda Accord Alternator

However, if the clutch engages but does not disengage when the AC is turned off, it may indicate a problem with the compressor itself.

2. Monitor Refrigerant Levels

Monitoring the refrigerant levels in your AC system is crucial for proper compressor functioning. If you suspect low refrigerant levels, you can use a pressure gauge to check the pressure on the low side of the system.

Low pressure may indicate insufficient refrigerant, while high pressure could suggest overcharging. However, it is important to note that properly diagnosing refrigerant issues requires specialized tools and knowledge, and it is best left to professionals.

3. Inspect for Refrigerant Leaks

Refrigerant leaks can lead to compressor problems and a loss of cooling efficiency. Inspect the AC system for signs of refrigerant leaks, such as oil stains, wet spots, or hissing sounds.

UV dye kits can also be used to identify leaks by adding a fluorescent dye to the system. However, it is recommended to consult a professional technician for leak detection and repair.

4. Clean the Condenser and Evaporator Coils

Over time, dirt, dust, and debris can accumulate on the condenser and evaporator coils, hindering heat transfer and reducing the compressor’s efficiency.

Regularly clean the coils using a soft brush or compressed air to remove any buildup. Take care not to damage the delicate fins on the coils. Keeping the coils clean will help maintain optimal performance and prevent compressor strain.

5. Check the Belt Tension

If you suspect a problem with the belt tension, visually inspect the belt for signs of wear or looseness. A loose or worn-out belt can affect the compressor’s operation and cooling efficiency. Adjust or replace the belt as necessary, following the manufacturer’s recommendations and guidelines.

6. Inspect Electrical Connections

Ensure that all electrical connections related to the AC system, including the compressor clutch, are secure and free from corrosion.

Loose or corroded connections can lead to intermittent operation or complete failure of the compressor. Clean and tighten any loose or corroded connections, or seek professional assistance if needed.

7. Clean or Replace Air Filters

Clogged or dirty air filters can restrict airflow to the AC system, leading to reduced cooling efficiency and potential compressor strain.

Regularly clean or replace the air filters according to the manufacturer’s recommendations to ensure proper airflow and prevent compressor problems.

8. Keep the AC System Running

Running your AC system regularly, even during the colder months, can help prevent compressor issues. Regular operation helps keep the compressor’s internal components lubricated and prevents them from seizing. It also allows you to detect any potential problems early on.

9. Protect the AC System from Direct Sunlight

Parking your 2007 Honda Odyssey in shaded areas or using sunshades can help protect the AC system from excessive heat and reduce the strain on the compressor. Direct sunlight can cause the system to work harder and increase the risk of overheating and compressor failure.

10. Follow Manufacturer’s Maintenance Guidelines

Adhering to the manufacturer’s maintenance guidelines is essential for preventing AC compressor problems. Regular inspections, filter replacements, refrigerant checks, and system cleanings are crucial for the optimal functioning and longevity of your AC compressor. Consult your vehicle’s owner manual for specific maintenance recommendations.

Key Points:

- Visually inspect the compressor clutch to ensure proper engagement and disengagement.

- Monitor refrigerant levels using a pressure gauge, but consult professionals for accurate diagnosis.

- Inspect the AC system for signs of refrigerant leaks, such as oil stains or hissing sounds.

- Clean the condenser and evaporator coils regularly to maintain optimal heat transfer.

- Check the belt tension and adjust or replace the belt as necessary.

- Ensure all electrical connections related to the AC system are secure and free from corrosion.

- Clean or replace air filters regularly to prevent airflow restrictions and compressor strain.

- Run the AC system regularly to keep internal components lubricated and detect potential problems.

- Park in shaded areas or use sunshades to protect the AC system from excessive heat.

- Follow the manufacturer’s maintenance guidelines for regular inspections, cleanings, and filter replacements.

- Catalytic Converter Price by Model - April 20, 2025

- Catalytic Converter Price Lookup: A Complete Guide - April 20, 2025

- Catalytic Converter Price in the UK: What You Need to Know - April 19, 2025