This post contains affiliate links. This means I will make a commission at no extra cost to you should you click through and make a purchase [ “As an Amazon Associate, I earn from qualifying purchases.” ]. Read the full disclosure here.

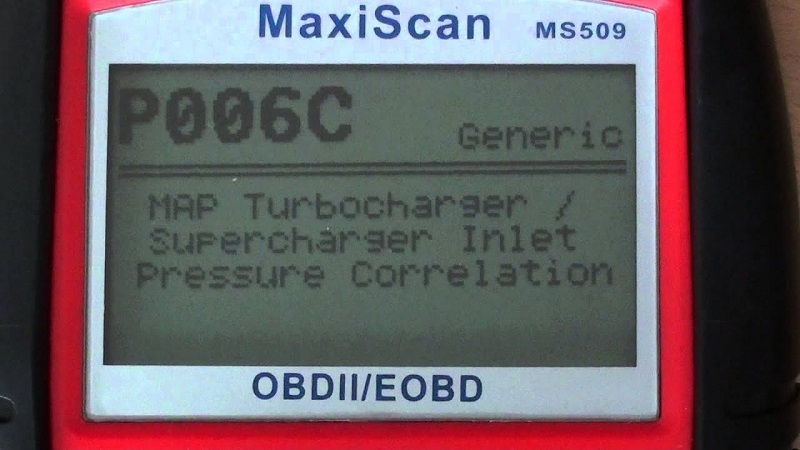

P006C Code MAP – Turbocharger/Supercharger Inlet Pressure Correlation GuideMechanic.Com In the intricate ecosystem of automotive diagnostics, deciphering the alphanumeric codes that appear on a vehicle’s onboard diagnostic system can be akin to solving a puzzle.

Among these codes, the P006C stands out, representing a potential issue with the correlation between the manifold absolute pressure (MAP) sensor and the turbocharger or supercharger inlet pressure within the engine system.

Understanding this code, its implications, and the underlying causes is crucial for maintaining optimal engine performance and reliability.

See Also: P006A MAP – Mass or Volume Air Flow Correlation Bank 1

To grasp the significance of the P006C trouble code, it’s essential to first understand the key components involved:

Manifold Absolute Pressure (MAP) Sensor:

The MAP sensor is a critical component of the engine management system, responsible for measuring the pressure within the intake manifold.

This data is utilized by the engine control unit (ECU) to adjust fuel injection timing and optimize engine performance under varying operating conditions.

Turbocharger/Supercharger Inlet Pressure:

In vehicles equipped with forced induction systems such as turbochargers or superchargers, the inlet pressure refers to the air pressure entering the compressor side of the forced induction system. This pressure is crucial for increasing engine power output by compressing air before it enters the combustion chamber.

Now, let’s delve into the meaning behind the P006C trouble code:

The P006C code specifically indicates a correlation issue between the readings from the MAP sensor and the turbocharger or supercharger inlet pressure sensor.

In simpler terms, the data collected by these sensors does not align as expected, signaling a potential discrepancy within the engine system. This misalignment can lead to various performance issues and may impact engine power delivery and efficiency.

Several factors could contribute to triggering the P006C trouble code:

Sensor Malfunction:

Both the MAP sensor and the turbocharger or supercharger inlet pressure sensor are susceptible to wear and tear over time.

Factors such as exposure to heat, vibration, or contaminants can lead to sensor degradation or failure, resulting in inaccurate readings and triggering the P006C code.

Faulty Wiring or Connectors:

Electrical issues such as corroded wires, loose connections, or damaged connectors can disrupt the communication between the sensors and the ECU. This interference can cause erroneous data transmission and trigger the P006C trouble code.

Turbocharger/Supercharger Issues:

Problems within the turbocharger or supercharger system, such as leaks, compressor wheel damage, or wastegate malfunctions, can affect inlet pressure readings. These issues compromise the effectiveness of the forced induction system and may lead to discrepancies between the MAP sensor and inlet pressure sensor readings.

Intake System Leaks:

Any leaks within the intake system, such as cracked hoses, loose connections, or faulty gaskets, can disrupt airflow and affect pressure readings. These leaks can lead to discrepancies between the MAP sensor and inlet pressure sensor readings, triggering the P006C code.

Engine Tuning or Modifications:

Aftermarket engine modifications or tuning changes can alter engine parameters and affect sensor readings. Improperly calibrated or mismatched components can lead to discrepancies between the MAP sensor and inlet pressure sensor readings, resulting in the activation of the P006C trouble code.

When confronted with the P006C trouble code, prompt diagnosis and resolution are essential to prevent further damage and restore optimal engine performance. Here’s a systematic approach to troubleshooting:

Scan for Additional Codes:

Conduct a comprehensive diagnostic scan to check for any additional trouble codes that may offer insight into related issues within the engine system.

Inspect Sensors and Wiring:

Begin by visually inspecting the MAP sensor, turbocharger or supercharger inlet pressure sensor, and their respective wiring and connectors. Look for signs of damage, corrosion, or disconnection that may impair sensor functionality.

Check for Turbocharger/Supercharger Issues:

Inspect the turbocharger or supercharger system for any signs of leaks, damage, or malfunctions. Pay particular attention to components such as the compressor wheel, wastegate, and boost control solenoid.

Test Sensor Readings:

Utilize a diagnostic scan tool to monitor the real-time readings from both the MAP sensor and the turbocharger or supercharger inlet pressure sensor while the engine is running. Compare these readings to specifications provided by the manufacturer to identify any discrepancies.

Perform Component Tests:

Conduct specific tests on individual components, such as the MAP sensor, turbocharger or supercharger inlet pressure sensor, or related circuits, to pinpoint the exact source of the problem.

Address Identified Issues:

Once the culprit is identified, take necessary measures to address the underlying issue. This may involve repairing or replacing faulty sensors, resolving turbocharger or supercharger issues, fixing intake system leaks, or reverting engine tuning or modifications.

Clear Codes and Test Drive:

After resolving the problem, clear the trouble codes from the ECU’s memory and take the vehicle for a test drive. Monitor for any recurring issues and ensure that the problem has been successfully resolved.

In conclusion, the P006C MAP – Turbocharger/Supercharger Inlet Pressure Correlation trouble code serves as a diagnostic indicator of potential discrepancies between the MAP sensor and the turbocharger or supercharger inlet pressure sensor readings within the engine system.

While deciphering these codes may pose a challenge, understanding their implications and following a systematic troubleshooting approach is crucial for identifying and resolving underlying issues.

By addressing the root cause promptly, drivers and mechanics can maintain the health and efficiency of the engine system, ensuring optimal performance and power delivery.

See Also: P006B MAP – Exhaust Pressure Correlation

- BMW Catalytic Converter Price: What You Need to Know - April 24, 2025

- Scrap Catalytic Converter Price - April 24, 2025

- Honda CR-V Catalytic Converter Price - April 24, 2025