This post contains affiliate links. This means I will make a commission at no extra cost to you should you click through and make a purchase [ “As an Amazon Associate, I earn from qualifying purchases.” ]. Read the full disclosure here.

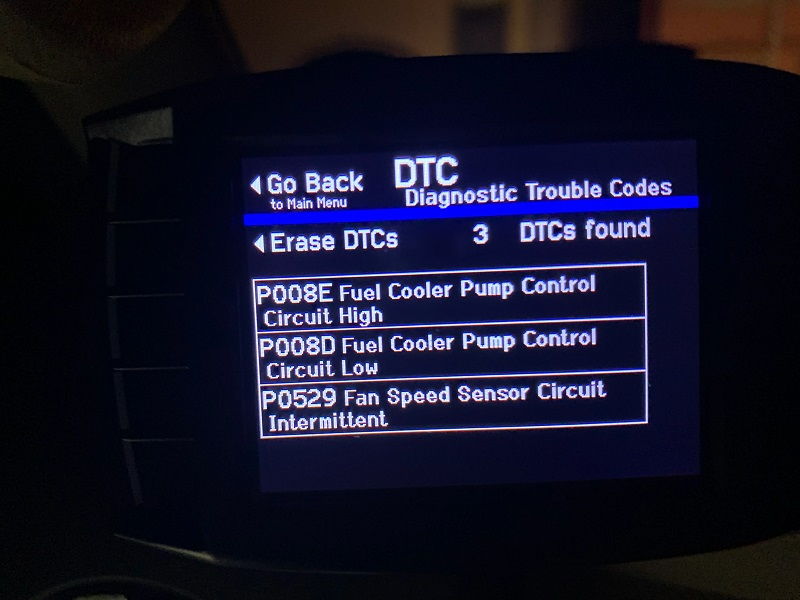

P008E Fuel Cooler Pump Control Circuit High GuideMechanic.Com The illumination of the check engine light can serve as an early warning sign of underlying issues. One such issue is highlighted by the P008E trouble code, which specifically points to a problem within the fuel cooler pump control circuit.

This code indicates that the voltage within the circuit has exceeded the expected threshold, potentially leading to issues with the fuel cooler pump’s operation. In this comprehensive article, we’ll delve into the intricacies of the P008E code, exploring its meaning, symptoms, potential causes, diagnostic procedures, and solutions.

P008E Fuel Cooler Pump Control Circuit High

Understanding the P008E Code:

The P008E code is a diagnostic trouble code that is part of the OBD-II system, indicating a high voltage condition within the fuel cooler pump control circuit. In vehicles equipped with a fuel cooler, the pump plays a crucial role in maintaining optimal fuel temperature by circulating it through the cooler. When the voltage within the control circuit exceeds the expected range, it triggers the illumination of the check engine light and the logging of the P008E trouble code.

Symptoms of P008E Code:

Identifying the symptoms associated with the P008E code is crucial for prompt diagnosis and resolution. While the symptoms may vary depending on the severity of the issue and the vehicle’s make and model, common indicators include:

Check Engine Light (CEL) Illumination: The illumination of the check engine light is often the first indication of a potential issue with the fuel cooler pump control circuit.

Increased Fuel Temperature: A malfunctioning fuel cooler pump can lead to increased fuel temperature, potentially resulting in engine performance issues and reduced efficiency.

Fuel Temperature Warning: Some vehicles may have a dedicated warning light or message on the instrument cluster indicating high fuel temperature.

Decreased Performance: Elevated fuel temperature can adversely affect engine performance, resulting in decreased power output and fuel efficiency.

Potential Causes:

Determining the underlying cause of the P008E code requires a systematic approach, considering various components within the fuel cooler pump control circuit. Some common culprits include:

Faulty Fuel Cooler Pump: A malfunctioning fuel cooler pump may have internal electrical issues or mechanical failures that result in a high voltage condition within the control circuit.

Wiring Issues: Damage, corrosion, or poor connections within the wiring harness associated with the fuel cooler pump control circuit can lead to voltage spike issues.

Short Circuit: A short circuit within the control circuit can cause an abrupt increase in voltage, triggering the P008E trouble code.

Faulty Relay: A defective relay responsible for supplying power to the fuel cooler pump may fail to regulate voltage properly, leading to a high voltage condition within the circuit.

Control Module Malfunction: An issue with the control module responsible for managing the fuel cooler pump operation can result in erratic voltage output, causing the circuit to enter a high voltage state.

Diagnostic Procedure:

See Also: P008F Engine Coolant Temperature/Fuel Temperature Correlation

Diagnosing the P008E code typically involves a combination of visual inspection, testing, and the use of diagnostic tools. A step-by-step diagnostic procedure may include:

Visual Inspection: Inspect the wiring harness, connectors, and components associated with the fuel cooler pump control circuit for any signs of damage, corrosion, or short circuits.

Check Battery Voltage: Test the vehicle’s battery voltage to ensure it is within the manufacturer’s specified range. A voltage spike caused by a faulty battery can trigger the P008E trouble code.

Test Fuel Cooler Pump: Use a multimeter to test the fuel cooler pump for voltage output when the ignition is turned on. Verify that it is receiving the correct voltage from the control circuit.

Test Relays: Test the relays related to the fuel cooler pump circuit to ensure they are functioning correctly and regulating voltage properly.

Check Control Module: Test the control module responsible for managing the fuel cooler pump operation to ensure it is functioning correctly and providing the correct voltage output.

P008E Fuel Cooler Pump Control Circuit High

Repair and Solutions:

Once the root cause of the P008E code has been identified, appropriate repairs can be undertaken to resolve the issue. Depending on the underlying problem, solutions may include:

Replacing the Fuel Cooler Pump: If the fuel cooler pump is found to be faulty or malfunctioning, it should be replaced with a new unit to restore proper operation.

Repairing Wiring: Repair or replace any damaged wiring or connectors in the fuel cooler pump control circuit to ensure a secure electrical connection and eliminate voltage spike issues.

Addressing Short Circuits: Identify and repair any short circuits within the control circuit, ensuring proper insulation and connection of wires.

Replacing Relays: If a faulty relay is identified, replace it with a new component of the same rating to ensure proper voltage regulation within the circuit.

Addressing Control Module Issues: If the control module is determined to be faulty, it may need to be repaired or replaced to rectify voltage output issues and restore proper operation of the fuel cooler pump.

Conclusion:

The P008E code, indicating a high voltage condition within the fuel cooler pump control circuit, presents challenges for vehicle owners and mechanics alike. However, with a systematic diagnostic approach and thorough understanding of potential causes, accurate diagnosis and effective solutions can be achieved.

Whether it involves replacing a faulty fuel cooler pump, repairing wiring issues, or addressing control module malfunctions, timely intervention is essential to restore optimal vehicle performance and prevent potential damage. As always, consulting with a qualified mechanic or technician is recommended for proper diagnosis and repair.

- P0000 Through P0099: Understanding OBD-II Trouble Codes - February 11, 2025

- P0000 Through P0199: Understanding OBD-II Trouble Codes - February 10, 2025

- P0080 Exhaust Valve Control Solenoid Circuit High (Bank 1) - February 9, 2025