This post contains affiliate links. This means I will make a commission at no extra cost to you should you click through and make a purchase [ “As an Amazon Associate, I earn from qualifying purchases.” ]. Read the full disclosure here.

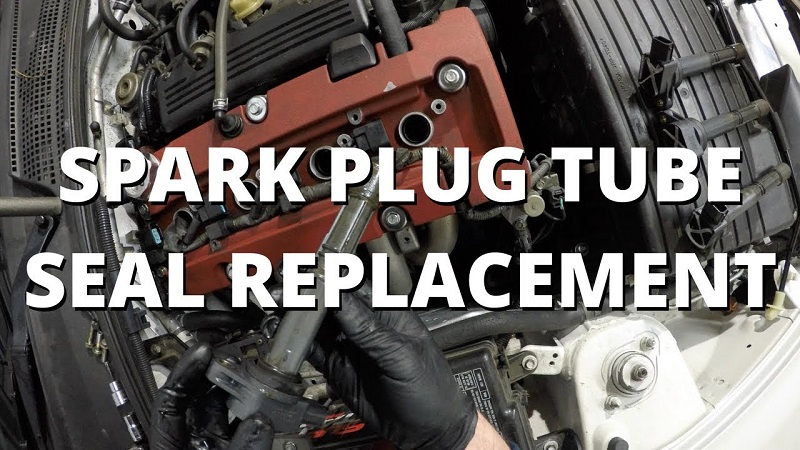

Spark Plug Tube Seal Replacement GuideMechanic.Com When it comes to maintaining the health and performance of your vehicle’s engine, one crucial aspect that often gets overlooked is the spark plug tube seal.

These small but mighty components play a vital role in keeping your engine running smoothly and efficiently.

Over time, however, these seals can wear out or become damaged, leading to a host of issues, including oil leaks, misfires, and decreased fuel efficiency.

In this blog article, we will provide you with a comprehensive guide on spark plug tube seal replacement, covering everything you need to know to tackle this task with confidence.

From understanding the importance of these seals to step-by-step instructions on how to replace them, we’ve got you covered. So, let’s dive in and ensure your engine is performing at its best!

What are Spark Plug Tube Seals?

Spark plug tube seals are small rubber or silicone gaskets that are placed between the spark plug tubes and the valve cover. Their main function is to prevent oil from leaking into the spark plug tubes.

By sealing off these tubes, the seals help maintain the integrity of the combustion process, ensuring that the spark plugs spark properly and that the engine runs smoothly.

There are different types of spark plug tube seals available in the market, including O-ring seals, gasket seals, and rubber seals.

O-ring seals are typically made of rubber and have a round cross-section, while gasket seals are flat and made of materials like silicone or rubber. Rubber seals are often pre-formed and designed specifically for certain engine models.

See Also: Spark Plug Service: DIY or Professional?

Each type of seal has its own advantages and disadvantages. O-ring seals are known for their durability and resistance to high temperatures, making them ideal for high-performance engines.

Gasket seals, on the other hand, provide a reliable and tight seal, but they may require additional sealant to prevent leaks.

Rubber seals are easy to install and are often cost-effective, but they may not offer the same level of durability as other types of seals.

Signs of Failing Spark Plug Tube Seals

Recognizing the signs of failing spark plug tube seals is crucial for timely replacement. Ignoring these signs can lead to more serious engine problems and costly repairs down the line. Here are some common indicators that your spark plug tube seals may need replacement:

1. Oil Leaks Around the Spark Plugs

One of the most noticeable signs of failing spark plug tube seals is oil leaks around the spark plugs. If you notice oil pooling around the spark plugs or see oil-soaked wires when inspecting the engine, it’s likely that the seals are no longer effectively sealing off the spark plug tubes. This can result in oil seeping into the combustion chamber, leading to reduced engine performance and potential misfires.

2. Rough Idling

Failing spark plug tube seals can also cause rough idling, where the engine may vibrate or produce unusual sounds when at idle.

This is often caused by oil leaking into the combustion chamber and affecting the combustion process. As a result, the engine may struggle to maintain a steady and smooth idle, affecting overall performance.

3. Reduced Engine Power

If you notice a decrease in engine power or responsiveness, failing spark plug tube seals could be the culprit.

When oil leaks into the spark plug tubes, it can interfere with the spark plug’s ability to ignite the air-fuel mixture properly.

This can lead to incomplete combustion, resulting in reduced power output and overall engine performance.

4. Decreased Fuel Efficiency

Fuel efficiency can also be negatively impacted by failing spark plug tube seals. As oil leaks into the combustion chamber, it can contaminate the air-fuel mixture, causing it to burn less efficiently. This can lead to increased fuel consumption and a decrease in overall miles per gallon.

5. Check Engine Light

In some cases, a failing spark plug tube seal can trigger the check engine light on your dashboard. This occurs when the engine’s sensors detect irregularities in the combustion process or other performance-related issues.

If the check engine light illuminates, it’s important to have your vehicle inspected by a professional to determine the exact cause of the problem.

Tools and Materials Required

Before you begin the spark plug tube seal replacement process, it’s crucial to have the necessary tools and materials on hand. Here’s a comprehensive list of what you’ll need:

1. Socket Set

A socket set with various sizes of sockets will be required to remove the necessary components during the replacement process. Make sure you have both metric and standard sizes to accommodate different engine models.

2. Spark Plug Socket

A spark plug socket is specifically designed to fit over the spark plug, allowing for easy removal and installation.

See Also: RC12YC Cross Reference: Testing and Reviews

It typically has a rubber insert to protect the spark plug’s ceramic insulator from damage during the process.

3. Ratchet

A ratchet is an essential tool for loosening and tightening bolts, nuts, and other fasteners. Make sure you have a ratchet that is compatible with your socket set.

4. Torque Wrench

A torque wrench is used to tighten the spark plugs to the manufacturer’s specified torque. This ensures that the spark plugs are securely fastened without being over-tightened, which can cause damage to the engine.

5. Pry Bar or Screwdriver

A pry bar or screwdriver may be necessary to remove certain components, such as the valve cover or ignition coils. These tools can help gently pry or lift components without causing damage.

6. New Spark Plug Tube Seals

Of course, you’ll need new spark plug tube seals to replace the old ones. Ensure that you have the correct seals for your specific engine model.

It’s recommended to purchase high-quality seals from reputable manufacturers to ensure a proper and long-lasting seal.

7. Sealant (if necessary)

Depending on the type of seals you are using and the manufacturer’s recommendations, you may need to apply a sealant to ensure a tight and leak-free seal. Be sure to check the instructions provided with your seals or consult with a professional if you’re unsure.

8. Clean Cloth or Rag

A clean cloth or rag will be handy for wiping away any dirt, debris, or oil that may accumulate during the replacement process. Keeping the work area clean will help prevent any contaminants from entering the engine.

9. Gasket Scraper or Razor Blade

If there is any old gasket material or residue left on the valve cover or other components after removing the old seals, a gasket scraper or razor blade can be used to carefully scrape it off. Ensure that you do this gently to avoid scratching or damaging the surfaces.

10. Safety Glasses and Gloves

Lastly, don’t forget to prioritize safety. Wear safety glasses to protect your eyes from any debris that may be dislodged during the replacement process. Additionally, gloves can help protect your hands from cuts or burns.

Step-by-Step Guide to Replacing Spark Plug Tube Seals

Now that you have all the necessary tools and materials, it’s time to dive into the spark plug tube seal replacement process. Follow these step-by-step instructions to ensure a successful replacement:

Step 1: Prepare the Work Area

Start by parking your vehicle on a flat surface and engaging the parking brake. Allow the engine to cool down completely before beginning the replacement process to avoid any risk of burns.

Open the hood and locate the engine. Clean the surrounding area to remove any dirt, debris, or oil that may have accumulated.

Step 2: Remove the Necessary Components

Begin by removing any components that may obstruct access to the spark plug tubes and valve cover. This may include the air intake duct, engine cover, or ignition coils.

Refer to your vehicle’s service manual or consult with a professional if you’re unsure about which components to remove.

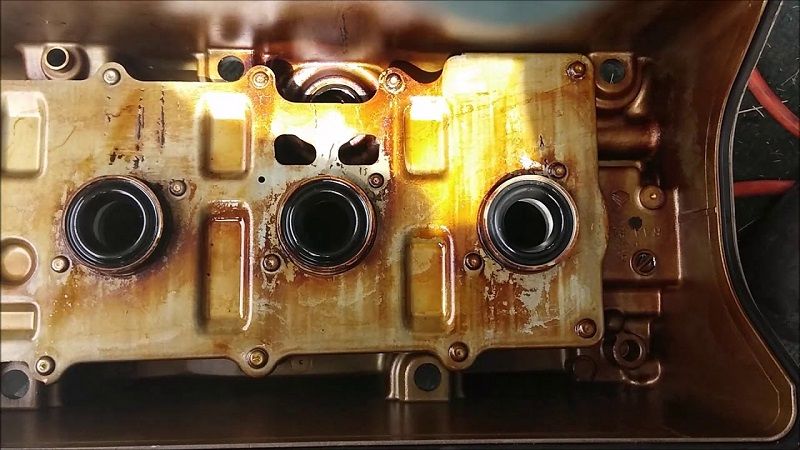

Step 3: Remove the Valve Cover

Using a socket wrench or ratchet, carefully remove the bolts that secure the valve cover in place. Gently lift the valve cover off, taking care not to damage any surrounding components.

If the valve cover seems stuck, you may need to use a pry bar or screwdriver to gently pry it loose. Set the valve cover aside on a clean surface.

Step 4: Inspect the Spark Plug Tubes

With the valve cover removed, inspect the spark plug tubes and the old seals for any signs of damage, wear, or oil accumulation.

See Also: Installing Spark Plugs

If the tubes are dirty or oily, clean them with a cloth or rag. Ensure that the tubes are free from any debris before proceeding.

Step 5: Remove the Old Spark Plug Tube Seals

Using a pair of pliers or your fingers, carefully grip the old spark plug tube seals and pull them straight out. Take your time and be gentle to avoid damaging the surrounding components.

If the seals are stubborn and difficult to remove, you may need to use a seal puller tool or a small flathead screwdriver to pry them out.

Step 6: Clean and Prepare the Spark Plug Tube Openings

After removing the old seals, it’s essential to clean and prepare the spark plug tube openings before installing the new seals. Use a clean cloth or rag to wipe away any dirt, debris, or oil residue.

Make sure the tube openings are completely clean and dry before proceeding to the next step. This will ensure a proper seal and prevent any contaminants from entering the engine.

Step 7: Apply Sealant (if necessary)

Depending on the type of seals you are using and the manufacturer’s recommendations, you may need to apply a sealant to ensure a tight and leak-free seal. If sealant is required, carefully apply a thin and even layer to the outer surface of each new spark plug tube seal.

Be sure to follow the instructions provided with your seals or consult with a professional if you’re unsure about the application process.

Step 8: Install the New Spark Plug Tube Seals

Take the new spark plug tube seals and carefully insert them into the spark plug tube openings. Ensure that they are placed securely and seated properly.

Use your fingers or a seal installation tool to push them in until they are flush with the top of the spark plug tube openings. Take care not to damage the seals during installation.

Step 9: Reinstall the Valve Cover

Once the new spark plug tube seals are installed, it’s time to reassemble the valve cover. Carefully position the valve cover back onto the engine, aligning it with the bolt holes. Start by hand-tightening the bolts to ensure proper alignment.

Then, using a torque wrench, tighten the bolts according to the manufacturer’s specified torque settings. Be sure to follow the recommended torque sequence to evenly distribute the tightening force.

Step 10: Reinstall the Removed Components

With the valve cover securely in place, reattach any components that were removed earlier, such as the air intake duct, engine cover, or ignition coils.

Ensure that all connections are secure and properly tightened. Double-check that all bolts and fasteners are tightened to the recommended torque specifications.

Step 11: Start the Engine and Check for Leaks

Before closing the hood, start the engine and let it run for a few minutes. Listen for any unusual noises or vibrations that may indicate a problem.

Keep an eye out for any signs of oil leaks around the spark plug tubes or valve cover. If everything looks and sounds normal, you have successfully replaced the spark plug tube seals.

Common Mistakes to Avoid

While replacing spark plug tube seals may seem like a straightforward task, there are common mistakes that DIYers often make.

These mistakes can lead to improper sealing, further damage to the engine, or increased risk of future issues. Here are some common mistakes to avoid:

1. Rushing the Replacement Process

One of the biggest mistakes is rushing through the replacement process. Take your time and follow each step carefully.

Rushing can lead to improper installation, inadequate sealing, or damage to components. Give yourself enough time to complete the task without feeling rushed.

2. Neglecting to Clean the Spark Plug Tube Openings

Failure to clean the spark plug tube openings before installing the new seals can result in a poor seal and potential leaks.

Make sure you thoroughly clean the tube openings to remove any dirt, debris, or oil residue. This will ensure a clean surface for the new seals to adhere to.

3. Over-tightening or Under-tightening the Valve Cover Bolts

Properly tightening the valve cover bolts is crucial to ensure a secure seal without damaging the valve cover or engine. Over-tightening the bolts can cause the valve cover to warp or crack, leading to leaks.

See Also: Spark Plug O Ring Replacement Cost

Under-tightening can result in an inadequate seal and potential oil leaks. Use a torque wrench and follow the manufacturer’s recommended torque settings to achieve the correct tightness.

4. Reusing Old Spark Plug Tube Seals

Reusing old spark plug tube seals is not recommended. Over time, these seals can become worn, hardened, or damaged, compromising their ability to provide a proper seal.

Always use new seals when replacing the spark plug tube seals to ensure optimal performance and prevent future issues.

5. Not Following the Manufacturer’s Instructions

Each vehicle and engine may have specific requirements and recommendations for spark plug tube seal replacement.

Always consult the manufacturer’s instructions or service manual for your specific vehicle to ensure you are following the correct procedures and using the recommended tools, materials, and torque specifications.

Maintenance Tips to Extend the Lifespan of Spark Plug Tube Seals

While replacing the spark plug tube seals is an essential maintenance task, taking preventive measures can help extend their lifespan and maximize their effectiveness. Here are some maintenance tips to keep your spark plug tube seals in optimal condition:

1. Regularly Check for Oil Leaks

Monitor your vehicle for any signs of oil leaks around the spark plug tubes or valve cover. If you notice any oil accumulation or wetness, address the issue promptly. Oil leaks can accelerate seal deterioration and lead to more significant engine problems if left unresolved.

2. Use High-Quality Engine Oil

Using high-quality engine oil that meets the manufacturer’s specifications can contribute to the longevity of the spark plug tube seals.

Quality oil helps maintain proper lubrication and reduces the risk of premature seal deterioration. Regularly change the engine oil according to the recommended intervals to keep the seals and the engine in good condition.

3. Avoid Over-tightening the Spark Plugs

When reinstalling the spark plugs after replacing the spark plug tube seals, avoid over-tightening them. Over-tightening can damage the spark plug threads or cause other issues.

Always follow the manufacturer’s recommended torque specifications for tightening the spark plugs to ensure a proper seal without causing damage.

4. Keep the Engine Clean

Regularly clean the engine and its components, including the valve cover and spark plug tubes. This helps prevent dirt, debris, and oil from accumulating and potentially causing seal damage.

Use a gentle cleaning solution and a soft brush or cloth to clean the engine surfaces, taking care not to splash any cleaning agents or water into the spark plug tube openings.

5. Schedule Regular Inspections

Include spark plug tube seal inspections as part of your routine vehicle maintenance. During regular inspections, check for signs of oil leaks, seal deterioration, or other issues. Address any problems promptly to prevent further damage and ensure optimal engine performance.

Frequently Asked Questions (FAQs)

Throughout our article, you may have developed some questions regarding spark plug tube seal replacement. Here are some common questions and their answers:

Q: How often should spark plug tube seals be replaced?

A: The lifespan of spark plug tube seals can vary depending on various factors, such as the quality of the seals, engine usage, and maintenance practices.

However, it is generally recommended to replace the spark plug tube seals every 60,000 to 100,000 miles or as indicated by the vehicle manufacturer’s maintenance schedule.

Q: Can I replace the spark plug tube seals myself, or should I hire a professional?

A: Spark plug tube seal replacement can be done as a DIY project if you have the necessary tools, skills, and confidence.

However, if you are unsure or uncomfortable performing the task, it’s always recommended to seek professional assistance.

See Also: 2003 Honda Accord Spark Plugs

Hiring a professional ensures that the job is done correctly and reduces the risk of potential mistakes or further damage to the engine.

Q: Can I reuse the old spark plug tube seals?

A: It is not recommended to reuse the old spark plug tube seals. Over time, these seals can deteriorate, harden, or become damaged, compromising their ability to provide an effective seal.

Always use new seals when replacing the spark plug tube seals to ensure optimal performance and prevent potential leaks.

Q: How can I prevent oil leaks around the spark plug tubes?

A: Regularly checking for oil leaks, using high-quality engine oil, avoiding over-tightening the spark plugs, keeping the engine clean, and scheduling regular inspections are some measures you can take to prevent oil leaks around the spark plug tubes.

By following these maintenance practices, you can help extend the lifespan of the spark plug tube seals and reduce the risk of leaks.

Q: Are spark plug tube seals model-specific?

A: Yes, spark plug tube seals are model-specific. It’s important to ensure that you purchase the correct seals for your specific engine model.

Consult the vehicle manufacturer’s specifications or consult with a professional to ensure you obtain the right seals for your vehicle.

Pros and Cons of DIY vs. Professional Replacement

When it comes to spark plug tube seal replacement, you have the option to either tackle the task yourself or hire a professional. Here are some pros and cons to consider for both approaches:

DIY Replacement:

Pros:

- Cost savings: Performing the replacement yourself can save you money on labor costs.

- Flexibility: Youhave control over the timing and can work at your own pace.

- Learning opportunity: DIY projects can provide valuable learning experiences and empower you to understand your vehicle better.

- Satisfaction: Successfully completing a DIY project can bring a sense of accomplishment and pride.

Cons:

- Skill and knowledge required: Spark plug tube seal replacement may require specific tools and expertise. If you’re unfamiliar with the process, there may be a learning curve.

- Time-consuming: The replacement process can be time-consuming, especially if it’s your first time performing the task.

- Potential for mistakes: DIY projects carry the risk of making errors, which could lead to further damage or the need for professional intervention.

Professional Replacement:

Pros:

- Expertise and experience: Professionals have the knowledge, skills, and experience to perform the replacement efficiently and correctly.

- Time-saving: Hiring a professional can save you time, as they are familiar with the process and can complete the task more quickly.

- Warranty or guarantee: Some professionals may provide warranties or guarantees for their work, providing you with peace of mind.

- Access to specialized tools and equipment: Professionals often have access to specialized tools and equipment that may be necessary for the replacement.

Cons:

- Cost: Hiring a professional for spark plug tube seal replacement will involve labor costs, which can vary depending on the service provider and location.

- Lack of control: You relinquish control over the timing and process to the professional, which may not align with your preferences or schedule.

- Dependency: Relying on a professional for the task means you may need to wait for an available appointment, potentially delaying the replacement.

Cost of Spark Plug Tube Seal Replacement

The cost of spark plug tube seal replacement can vary depending on several factors, including the vehicle make and model, the location, and whether you choose to perform the replacement yourself or hire a professional. Here’s a breakdown of the potential costs involved:

DIY Replacement:

If you decide to replace the spark plug tube seals yourself, the cost will primarily be for the new seals and any additional materials, such as sealant.

The price of spark plug tube seals can range from $10 to $50, depending on the type and quality. Sealant, if required, can cost around $10. Keep in mind that these prices are approximate and can vary depending on the supplier and location.

Professional Replacement:

If you choose to hire a professional for spark plug tube seal replacement, the cost will include labor charges in addition to the cost of the new seals and any other necessary materials.

Labor costs can vary significantly depending on the location, the service provider, and the complexity of the job. On average, you can expect to pay between $200 and $500 for professional spark plug tube seal replacement.

It’s recommended to obtain quotes from different service providers to find the best price for your specific circumstances.

Importance of Timely Spark Plug Tube Seal Replacement

Timely spark plug tube seal replacement is crucial for maintaining optimal engine performance and preventing more serious issues down the line. Here are some reasons why you should prioritize timely replacement:

Prevention of Oil Leaks:

One of the primary functions of spark plug tube seals is to prevent oil leaks into the spark plug tubes. Failing seals can lead to oil seepage, which can contaminate the spark plugs and affect their performance. By replacing the seals promptly, you can prevent oil leaks and avoid potential damage to the engine.

Optimal Engine Performance:

Properly functioning spark plug tube seals ensure that the spark plugs spark efficiently, contributing to optimal engine performance.

When the seals start to deteriorate or fail, the combustion process may be compromised, leading to misfires, rough idling, reduced power, and decreased fuel efficiency.

Timely replacement helps maintain the integrity of the combustion process and ensures that the engine operates at its best.

Prevention of Costly Repairs:

Ignoring failing spark plug tube seals can lead to more significant engine problems, such as damaged spark plugs, ignition coil failure, or even engine misfires.

These issues can result in costly repairs or even engine replacement. By addressing seal replacement promptly, you can prevent these costly repairs and prolong the lifespan of your engine.

Improved Fuel Efficiency:

Failing spark plug tube seals can contribute to decreased fuel efficiency. When oil leaks into the combustion chamber, it affects the air-fuel mixture and the combustion process.

This can lead to incomplete combustion and increased fuel consumption. By replacing the seals in a timely manner, you can help restore optimal fuel efficiency and save money on fuel costs.

In conclusion, spark plug tube seal replacement is a crucial maintenance task that should not be overlooked.

By understanding the signs of failing seals, following the step-by-step replacement guide, and implementing preventive maintenance measures, you can ensure optimal engine performance and prevent costly repairs.

Whether you choose to tackle the replacement yourself or hire a professional, prioritize timely replacement to keep your engine running smoothly and efficiently for miles to come.

Related video of Spark Plug Tube Seal Replacement: A Comprehensive Guide to Ensuring Optimal Engine Performance

- Old Lifted Diesel Trucks for Sale - December 18, 2025

- Big Lifted Diesel Trucks for Sale - December 17, 2025

- Cheap Lifted Diesel Trucks for Sale - December 16, 2025