This post contains affiliate links. This means I will make a commission at no extra cost to you should you click through and make a purchase [ “As an Amazon Associate, I earn from qualifying purchases.” ]. Read the full disclosure here.

Spark Plug Wires Replacement GuideMechanic.Com When it comes to maintaining a healthy engine, spark plug wires replacement is a crucial aspect that should not be overlooked.

These wires play a vital role in delivering the electrical energy from the ignition coil to the spark plugs, igniting the air-fuel mixture and powering the engine.

Over time, spark plug wires can wear out, leading to misfires, reduced fuel efficiency, and even engine damage.

In this comprehensive guide, we will explore the importance of spark plug wires replacement and provide you with all the necessary information to keep your engine running smoothly.

In this article, we will cover everything from understanding the signs of worn-out spark plug wires to the step-by-step process of replacing them.

See Also: 2007 Honda Accord Spark Plugs

Whether you are a seasoned car enthusiast or a novice DIYer, this guide will equip you with the knowledge and confidence to tackle this essential maintenance task.

Signs of Worn-out Spark Plug Wires

Spark plug wires undergo significant wear and tear over time due to exposure to heat, oil, and vibration. It is crucial to be able to recognize the signs indicating that your spark plug wires are due for replacement:

Misfiring Engine

One of the most common signs of worn-out spark plug wires is an engine misfire. This occurs when the spark plugs do not receive a consistent electrical charge, leading to incomplete combustion. You may notice a rough running engine, hesitation during acceleration, or a loss of power.

Rough Idling

If your engine is idling roughly or inconsistently, it could be a result of worn-out spark plug wires. When the wires fail to deliver a steady electrical charge to the spark plugs, the engine struggles to maintain a smooth idle. You may feel vibrations or hear unusual noises coming from the engine.

Decreased Fuel Efficiency

Spark plug wires that are past their prime can cause a decrease in fuel efficiency. When the wires fail to deliver the necessary spark to ignite the air-fuel mixture efficiently, the engine compensates by consuming more fuel. If you notice a significant drop in your mileage, it may be time to replace your spark plug wires.

Poor Acceleration

Worn-out spark plug wires can also result in poor acceleration. If you find that your vehicle is slower to respond when you press on the gas pedal or lacks the usual power, it could be due to a weak spark caused by deteriorating wires.

Increase in Emissions

When spark plug wires are nearing the end of their lifespan, they may not provide a strong enough spark to fully ignite the air-fuel mixture.

This incomplete combustion can lead to an increase in emissions, including higher levels of carbon monoxide and hydrocarbons.

See Also: Subaru Spark Plug Replacement

If you fail an emissions test or notice a strong smell of gasoline from your exhaust, it may be time to replace the spark plug wires.

Tools and Materials Needed for the Replacement

Before diving into the spark plug wires replacement process, it’s important to gather all the necessary tools and materials. Here is a list of items you will need:

New Spark Plug Wires

First and foremost, you will need a set of new spark plug wires. Make sure to choose wires that are compatible with your vehicle’s make and model. Consult your owner’s manual or do some research to ensure you select the right type of wires.

Safety Gloves and Glasses

Working on your vehicle’s engine can expose you to various hazards, including sharp edges and hot surfaces. It is essential to protect your hands with safety gloves and your eyes with safety glasses to prevent potential injuries.

Socket Set with Spark Plug Socket

A socket set is an essential tool for any DIYer. Make sure your set includes a spark plug socket that fits the size of your spark plugs. This socket will allow you to remove and install the spark plug wires efficiently.

Spark Plug Wire Puller

A spark plug wire puller can be a handy tool to have when removing the old wires. This tool provides a firm grip on the wire boot, making it easier to detach them from the spark plugs without damaging the wires or other engine components.

Wire Looms or Separators (Optional)

Using wire looms or separators can help organize and keep the spark plug wires neat and separated. While not necessary, they can be beneficial, especially in engines with a cluttered wire arrangement.

Precautions and Safety Measures

Before diving into the spark plug wires replacement process, it is crucial to take certain precautions and follow safety measures to ensure your well-being and prevent any damage to your vehicle:

Disconnect the Battery

Whenever working on the electrical components of your vehicle, it is essential to disconnect the battery to prevent any accidental electrical discharge or short circuits. Locate the battery and disconnect the negative terminal using a wrench or socket wrench.

Allow the Engine to Cool Down

Before starting the replacement process, it is important to allow the engine to cool down. Working around a hot engine can increase the risk of burns. Wait until the engine has had ample time to cool down before proceeding.

Work in a Well-Ventilated Area

When working on your vehicle, it is important to ensure proper ventilation. This helps prevent the build-up of harmful fumes and ensures you have enough fresh air circulating around you. If possible, work in an open garage or outside.

Wear Protective Gear

While working on your vehicle, always wear protective gear such as safety glasses and gloves. Safety glasses protect your eyes from debris, while gloves safeguard your hands from cuts, burns, and potential chemical exposure.

Follow Proper Removal and Installation Procedures

To prevent damage to the spark plug wires or other engine components, it is important to follow the correct removal and installation procedures.

See Also: Champion RJ19LM Cross Reference

Carefully disconnect the old wires from the spark plugs and ignition coil, and ensure the new wires are properly connected.

Locating the Spark Plug Wires

Locating the spark plug wires in your specific vehicle may vary depending on the make and model. Here are a few common methods to help you locate the spark plug wires:

Consult the Owner’s Manual

The owner’s manual is an invaluable resource when it comes to understanding your vehicle’s components and their locations. Consult the manual for information on the spark plug wire routing and identification.

Observe the Wire Routing

Look closely at the existing spark plug wires and observe their routing. Follow the wires from the ignition coil to the spark plugs, taking note of any clips or brackets that secure them in place. This will give you an idea of the general path the wires follow.

Use Online Resources and Forums

If you are having difficulty locating the spark plug wires, online resources and forums dedicated to your specific vehicle make and model can be a valuable source of information. Many experienced car enthusiasts are willing to share their knowledge and provide guidance.

Removing the Old Spark Plug Wires

Now that you have located the spark plug wires, it’s time to remove the old ones. Follow these step-by-step instructions to ensure a smooth removal process:

Step 1: Disconnect the Negative Battery Terminal

Start by disconnecting the negative battery terminal using a wrench or socket wrench. This will prevent any accidental electrical discharge or short circuits during the removal process.

Step 2: Locate the Spark Plug Wires

Refer to the methods mentioned earlier to locate the spark plug wires in your vehicle. Inspect the wires and take note of their arrangement before proceeding.

Step 3: Remove the Wire Boots

Gently grip the wire boot, the thick rubber piece at the end of each wire, and twist it back and forth while pulling it away from the spark plug. This will loosen the grip between the boot and the spark plug, allowing you to remove it without damaging the wire.

Step 4: Label the Wires

As you remove each spark plug wire, it is essential to label them to avoid confusion during installation. You can use masking tape and a marker to mark each wire with the corresponding cylinder number.

Step 5: Inspect the Wires

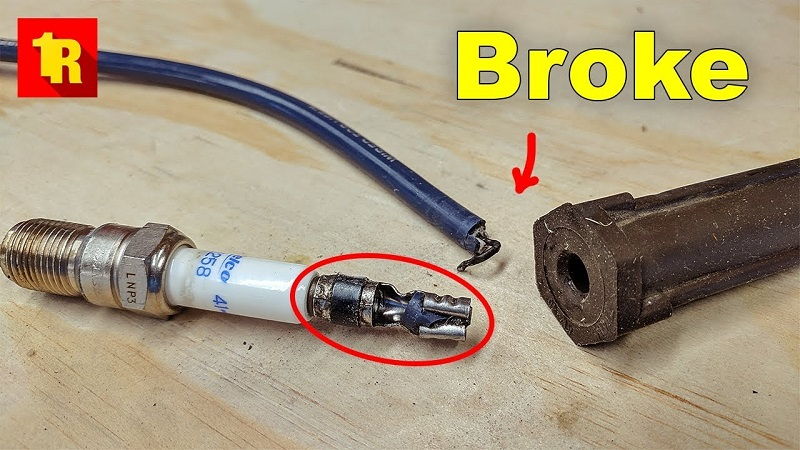

Take a closer look at the removed spark plug wires. Check for any signs of damage, such as cracks, excessive wear, or corrosion. If you notice any issues, it is best to replace the entire set of spark plug wires.

Inspecting the Ignition System

While you have the spark plug wires removed, it is a good idea to inspect other components of the ignition system to ensure they are in good condition. Here are a few components you should inspect:

Spark Plugs

Examine the spark plugs for signs of wear, such as fouling, excessive deposits, or worn electrodes. If the spark plugs show any signs of damage, it is recommended to replace them along with the spark plug wires.

Ignition Coil

Spark Plug Boots

Check the spark plug boots for any signs of wear or damage. Ensure that the boots fit securely onto the spark plugs and the ignition coil.

See Also: Torch F6RTC to Champion

If the boots are loose or damaged, it is recommended to replace them to maintain a proper connection and prevent misfires.

Ignition Wires and Cables

Inspect the ignition wires and cables for any cracks, fraying, or other signs of wear. These wires are responsible for transmitting electrical energy from the ignition coil to other components, such as the distributor or spark plug wires.

If you notice any issues with the ignition wires or cables, replace them to ensure a reliable electrical connection.

Choosing the Right Replacement Wires

When it comes to selecting the right spark plug wires for your vehicle, there are a few factors to consider:

Wire Material

Spark plug wires are available in different materials, including copper, carbon, and silicone. Each material has its advantages and disadvantages.

Copper wires offer excellent conductivity but may be more prone to interference. Carbon wires provide good performance and reduced radio frequency interference.

Silicone wires offer superior heat resistance and durability. Consider your specific needs and budget when choosing the wire material.

Resistance and Suppression

Some spark plug wires come with built-in resistance and suppression capabilities. These features help reduce radio frequency interference and electromagnetic interference, which can affect electronic components in your vehicle.

If you have a modern vehicle with sensitive electronic systems, consider opting for wires with resistance and suppression properties.

Length and Configuration

Ensure that the replacement spark plug wires are the correct length and configuration for your vehicle’s engine. Improperly sized wires can lead to misfires or poor performance.

Consult your vehicle’s specifications or the manufacturer’s guidelines to determine the appropriate length and configuration.

Quality and Brand

Choosing high-quality spark plug wires from reputable brands can ensure long-lasting performance and reliability. Research different brands and read customer reviews to find a brand that is known for producing reliable and durable spark plug wires.

Installing the New Spark Plug Wires

Now that you have the new spark plug wires ready, follow these step-by-step instructions to install them correctly:

Step 1: Refer to Labeling

Refer to the labels you created while removing the old spark plug wires. Match each wire with the corresponding cylinder number to ensure the correct installation.

Step 2: Apply Dielectric Grease

Apply a small amount of dielectric grease to the inside of each spark plug boot. This grease helps to create a moisture barrier and ensures a secure connection between the spark plug and the wire.

Step 3: Install the Wires

Starting with one wire at a time, insert the spark plug wire into the boot until you feel a click or resistance.

See Also: Torch F6RTC Spark Plug Cross Reference

Ensure that the wire is fully seated and secure in the boot. Repeat this process for each spark plug wire, following the correct routing and configuration.

Step 4: Connect to the Ignition Coil

Connect the other end of each spark plug wire to the corresponding terminal on the ignition coil. Ensure that the connections are secure and tight.

Step 5: Organize and Secure the Wires

Use wire looms or separators to organize and secure the spark plug wires. This will help prevent them from tangling or coming into contact with other engine components. Follow the original wire routing as much as possible for a clean and organized installation.

Step 6: Reconnect the Negative Battery Terminal

Once all the spark plug wires are installed and secured, reattach the negative battery terminal to restore power to the vehicle.

Testing the Ignition System

After replacing the spark plug wires, it is essential to test the ignition system to ensure everything is functioning correctly. Here are a few methods to verify the ignition system’s performance:

Start the Engine

Start the engine and listen for any unusual noises or vibrations. A properly functioning ignition system should provide smooth and consistent engine operation.

Check for Misfires

Monitor the engine for any signs of misfires, such as rough idling or hesitation during acceleration. If you notice any irregularities, it may indicate a problem with the spark plug wires or other ignition components.

Use an Ignition Tester

An ignition tester can be used to check the strength and consistency of the sparks produced by the spark plugs. Follow the instructions provided with the tester to perform the test accurately.

Perform a Road Test

Take your vehicle for a test drive to ensure that it accelerates smoothly, maintains power, and does not exhibit any signs of misfires or performance issues. Pay attention to any changes in engine behavior compared to before the spark plug wires replacement.

Maintenance Tips for Prolonged Spark Plug Wires Lifespan

To maximize the lifespan of your new spark plug wires and ensure optimal engine performance, follow these maintenance tips:

Regular Inspections

Periodically inspect the spark plug wires for any signs of wear, cracking, or damage. Catching issues early can prevent further damage and potential engine problems.

Keep the Engine Compartment Clean

Regularly clean the engine compartment to remove any debris or contaminants that could affect the performance of the spark plug wires. Be cautious when cleaning around electrical components and ensure the engine is cool before doing so.

Avoid Excessive Engine Heat

Excessive heat can deteriorate the performance of spark plug wires. Avoid prolonged high-temperature conditions and ensure that the engine cooling system is functioning properly.

Handle with Care

When working around the spark plug wires, handle them with care to avoid unnecessary bending or twisting. Rough handling can damage the wires and compromise their performance.

Follow Regular Maintenance Schedule

Follow the manufacturer’s recommended maintenance schedule for your vehicle, including regular tune-ups and inspections.

This will help detect any potential issues with the ignition system, including the spark plug wires, before they become major problems.

In conclusion, spark plug wires replacement is a vital maintenance task that should not be overlooked. By recognizing the signs of worn-out wires, gathering the necessary tools and materials, following proper precautions and safety measures, and understanding the step-by-step process, you can confidently replace your spark plug wires and ensure optimal engine performance.

Regular inspections, proper maintenance, and following the manufacturer’s guidelines will help prolong the lifespan of your spark plug wires and keep your engine running smoothly.

Don’t neglect this essential aspect of engine maintenance and enjoy the benefits of a well-functioning ignition system!

Related video of Spark Plug Wires Replacement: A Comprehensive Guide for Optimal Engine Performance

- Wynn’s Catalytic Converter Cleaner 325ml - April 17, 2025

- How to Use Catalytic Converter Cleaner - April 16, 2025

- Dura Lube Catalytic Converter Cleaner: Does It Work? - April 15, 2025